|

| Model | |

|---|

| Model | 816D |

| Configuration | STD | DS | CH | LGP | FR | Angle Blade |

| Main Specifications | |

|---|

| Operating Weight (w. SU blade, Ripper) | 18,230kg | 19,760kg | 18,490kg | 19,490kg | 19,910kg | 17,140kg |

| Ground Pressure (GB/T 30965) | 66.8kPa | 34.8kPa | 61.8kPa | 31.1kPa | 66.9kPa | 66.8kPa |

| Minimum Ground Clearance (Excludes Grouser Height) | 410mm |

| Gradeability | 30° |

| Engine | |

|---|

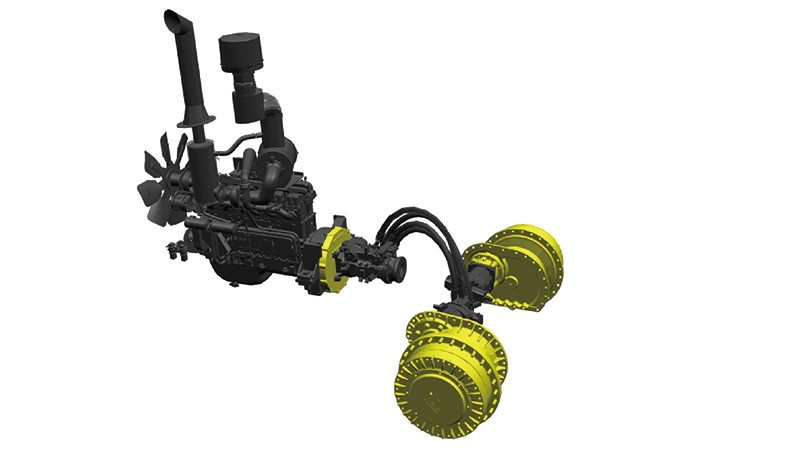

| Engine Model | WD10G178E25 |

| Advertised Power (ISO 14396) | 131kW |

| Rated Speed | 1,850r/min |

| Powertrain | |

|---|

| Transmission Type | Dual-path, closed loop electronically controlled hydrostatic drive system |

| Travel Speeds - Forward and Reverse | Infinitely variable speeds 0-10 km/h |

| Steering and Brake | hydrostatic steering, wet, multi-disc brake |

| Implement Hydraulic | |

|---|

| Type | center close, pilot control |

| System Pressure | 19MPa |

| Pump Type | Gear pump |

| Blades | |

|---|

| Blade Type | SU/S | LGP | LGP | U | SU Forestry/S Forestry | Angle Blade |

| Blade Capacity (ISO 9246) | 4.3m³/3.5m³ | 3.4m³ | 5.6m³ | 3.4m³ | 6m³/5.8m³ | 3.5m³ |

| Blade Width (w/End Bit) | 3,180mm/3,590mm | 4,410mm | 3,580mm | 4,410mm | 3,180mm/3,590mm | 3,970mm |

| Blade Height | 1,240mm/1,165mm | 1,000mm | 1,400mm | 1,000mm | 1,625mm/1,625mm | 1,090mm |

| Blade Lifting Height | 1,041mm | 1,055mm | 1,041mm | 1,055mm | 1,041mm | 1,067mm |

| Blade Digging Depth | 430mm | 470mm | 430mm | 470mm | 430mm | 430mm |

| Blade Tilt Height (Middle Hole) | 455mm | 470mm | 508mm | 470mm | 455mm | 455mm |

| Blade Weight (w/o Push Arm) | 1,390kg | 1,540kg | 1,640kg | 1,540kg | 1,555kg | 1,450kg |

| Minimum Turning Radius | 3,610kg | 3,740kg | 3,610kg | 3,740kg | 3,610kg | 3,610kg |

| Single Shank Rippers | |

|---|

| Type | N/A |

| Maximum Penetration (Shank Pinned in the Top Hole) | N/A |

| Maximum Clearance Under Tip (Shank Pinned in the Bottom Hole) | 615mm | N/A | 615mm | N/A | 615mm | N/A |

| Ripper Weight | N/A |

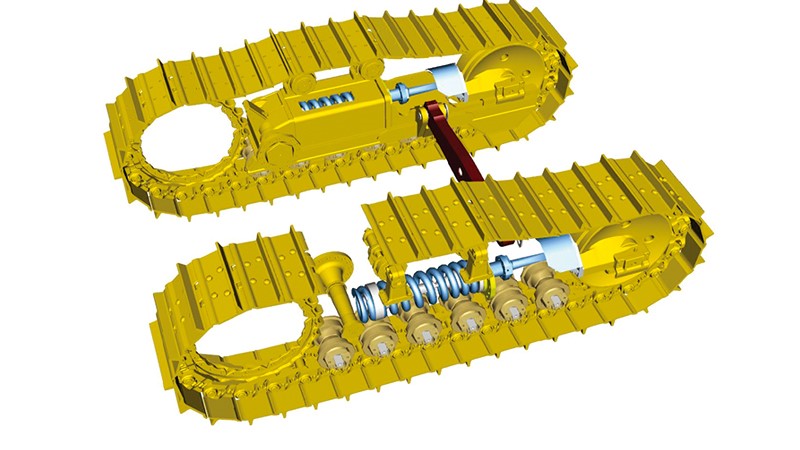

| Undercarriage | |

|---|

| Track Shoe Width | 510mm | 950mm | 560mm | N/A | 560mm | N/A |

| Track Shoes Number (Each Side) | 37 | 42 | 37 | 42 | 37 | 37 |

| Track Rollers Number (Each Side) | 6 | 7 | 6 | 7 | 6 | 6 |

| Carrier Roller Number (Each Side) | 2 | 2 | 2 | 2 | 2 | 2 |

|

|---|