Optimized Engine

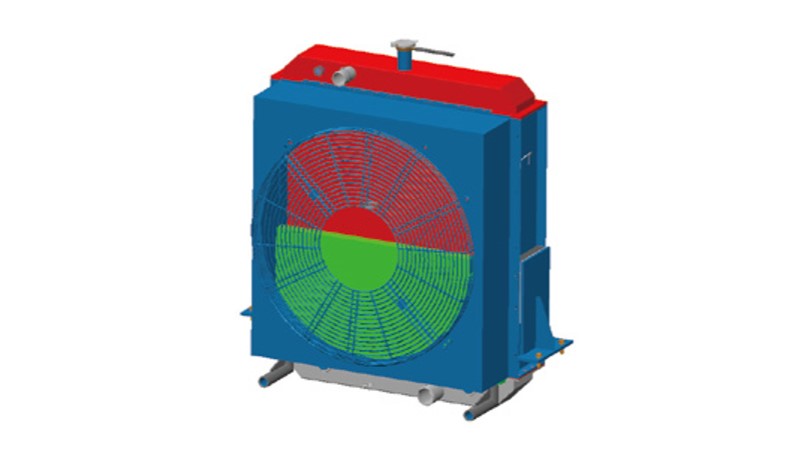

- Low speed engine with E-fan provides increased operating efficiency

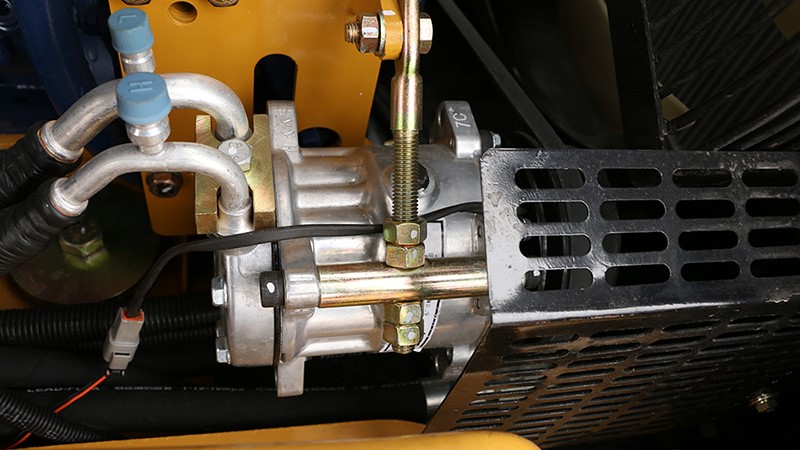

- Enhanced fuel pre-filter eliminates water and contaminant from fuel for best fuel system protection

- The 93 desert type air cleaner provides machine reliability in most severe applications. Oil-bath type oil filter is optional