The SEM F series Tier 2 Motor Grader is equipped with an SDEC engine and a PPPC load-sensing hydraulic system for consistent and precise blade movement and reduced fuel consumption. The SEM rear tandem axle, designed and manufactured by Caterpillar, leverages the proven Caterpillar tandem axle design to deliver differentiated reliability and a longer service life, resulting in lower owning & operating costs.

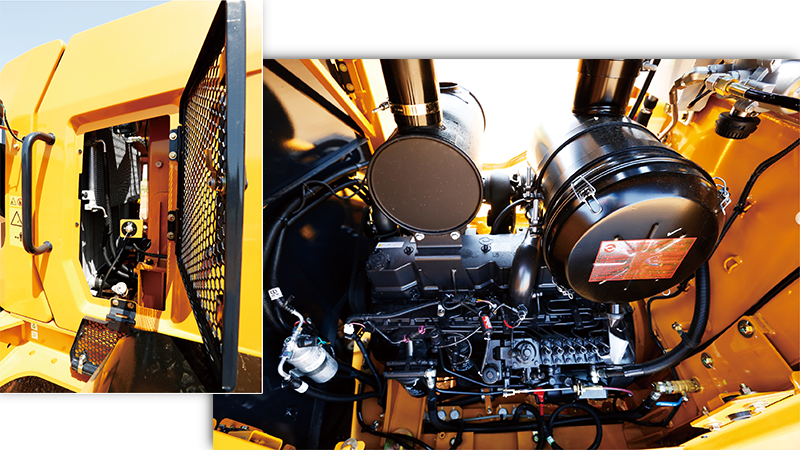

In response to customer suggestions and feedback, the new generation F series Motor Grader has been upgraded to better meet the needs of customers and further improve machine performance. This includes the removal of the transmission shaft, direct connection of the hydraulic pump to the gearbox, and a new molded engine hood with a contemporary aesthetic, providing the machine with a striking and impactful visual design.

With these enhancements, SEM's new F series Motor Grader offers improved competitiveness and solutions to support the success of our dealers and customers.

Operate in comfort

- Standard float function for high efficiency and simple operation.

- Caterpillar's classic lever control with a short distance and stroke.

- Adjustable console and seat with optimized ergonomics.

- Cab with improved airtightness and noise reduction.

- Added vents in the new dashboard and cab columns for increased comfort.

Low cost per hour

- Less heat and fuel consumption; load-sensing and PPPC hydraulic system offer increased efficiency.

- Hydraulic cooling fan, high efficiency in various ambient temperature conditions and enhances cooling effect.

- Caterpillar (Qingzhou) in-house tandem axle, final drive units with four planetary gears, oil-bath lubrication, and maintenance-free and adjustment-free chain support a higher carrying capability.

- Dismountable drawbar ball joint for easy replacement and maintenance.

Performance you need

- Up to 2 times more circle drive torque than the industry standard for increased working efficiency.

- PPPC hydraulic system ensures precise, predicable and consistent operational movement regardless of engine speed.

- Cab is mounted in the frontal frame to provide enhanced visibility for convenient operations.

- 7-hole linkbar of Electro Hydraulic pin puller offers excellent extensibility of the moldboard, delivering superior performance.